We want to make sure your custom apparel is perfect! Over our years of experience, there are specifics to printing that we have to work with; sharing our do’s and don’ts with you all will help you consider or avoid certain print techniques or placements.

PRINTING DO'S AND DON'TS

VIBRANCY WITH WHITE UNDERBASE

When printing colors on dark garments, we often suggest to print a white ink layer as an “underbase” in order for the colors to pop. The inks are not opaque and vibrant enough to print directly onto, for example, and black tee, so the white underbase serves as a ‘primer’ for the inks to achieve the correct brightness. One example is wanting to print a golden yellow design onto a navy blue tee. Though this is only a one color print, we generally print a white underbase for the yellow to appropriately pop. In the end, this job would be a two color print: white and golden yellow. Please account for the additional color and charges. If this happens, we often suggest to incorporate the white into the design for more variation and color- since it has to be printed anyway!

Often, customers prefer to print without a white underbase to achieve a ‘vintage effect’. Coupling this style onto fabrics like tri-blends and burnouts make a killer print!

PRINT>FLASH>PRINT WITH WHITE INK

When printing white as a single color on a dark garment, we suggest to print>flash>print the white ink, meaning, print to passes of white ink (as two layers) so the white becomes more vibrant on the dark garments. Working with dark garments often require an additional charge since it is a lengthier process to print.

Here is an example between a white ink with a single pass and a white ink with two passes.

ONE PASS OF WHITE INK (LEFT) ON DARK GARMENT SHIRTS ARE NOT EXTREMELY VIBRANT. MOST DARK GARMENTS REQUIRE A SECOND PASS OF WHITE (RIGHT) SO THAT THE DESIGN HAS A BRIGHT WHITE.

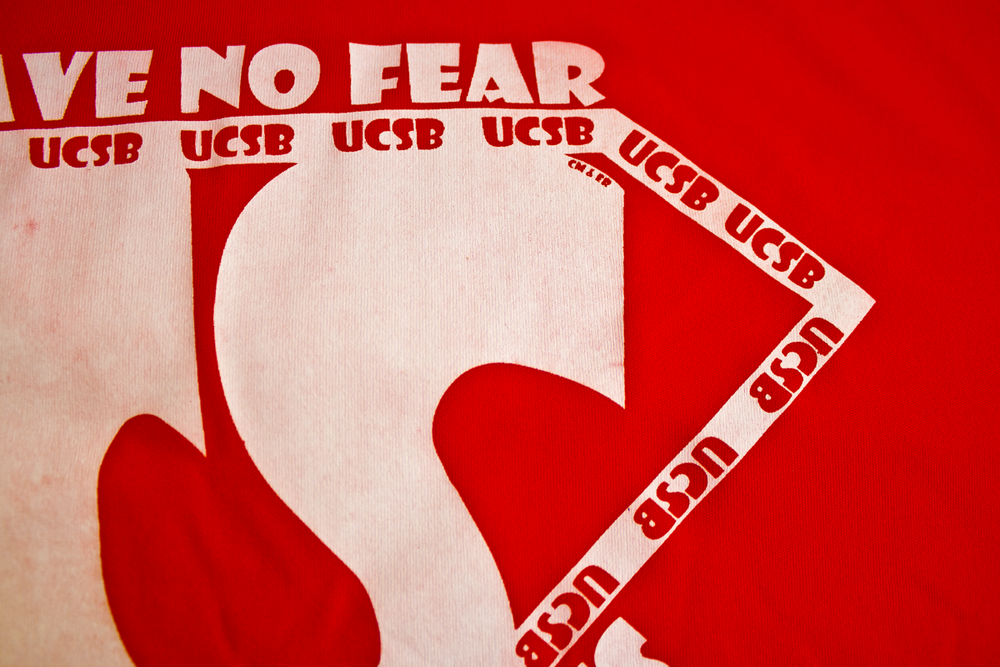

DYE MIGRATION ON POLYESTER FABRICS

Dye Migration is a process that most commonly occurs between standard screen printing inks and synthetic fibers. When sending printed apparel through the dryer at +300 degrees during the curing of the inks, the dyes in the polyester fabric sublimates, or turns gaseous. In gaseous form, the dyes seep into the ink layer, tinting the color of the ink. This occurs most often in colors like red, navy, maroon, greens, and other dark colors. Though using low-bleed inks and adjusting heat levels during the curing process help with the migration, please be aware that discoloration and migration into the inks can still occur. Here is an example of a white ink on a red cotton tee versus a red polyester dri-fit.

DYE MIGRATION CAN OCCUR WITH BRIGHT POLYESTER COLORS, LIKE RED. ALTHOUGH WE DO OUR BEST TO USE LOW-BLEED INKS AND MINIMIZE THE NECESSARY HEAT DURING THE CURING PROCESS, PLEASE BE AWARE THAT MIGRATION CAN OCCUR. THIS EXAMPLE SHOWS HOW SOME OF THE RED IS BLEEDING INTO THE WHITE INK.

TRI-BLEND TEES AND PRINT SUGGESTIONS

Tri-blend material is generally thin and sensitive to heat. Because of this, we do not prefer to use white underbases or flash units to cure each color of ink after being printed. Without an underbase, tri-blend tees will have a faded/vintage look, which is what the shirts were intended for! This is super popular!

A SINGLE PASS OF GOLD AND CREAM (WITHOUT A WHITE UNDERBASE UNDER) ALLOWS FOR THE TEXTURE OF THE TRIBLEND TO COME THROUGH. THIS IS A VERY POPULAR LOOK WITH THESE BLENDS! ADDING A DISTRESSED FILTER ON THE ARTWORK, EVEN ADDS MORE TO THE VINTAGE FEEL.

PRINTING OVER SEAMS, POCKETS, OR ZIPPER

For screen printing, it is important to have a flat surface. As we pass the ink through the screen (the stencil of the design), the flatness of the garment allows for the ink to lay softly on the fabric. Any seam, zipper, hem, or collar will affect the consistency of the print, since it creates thicker portions of the garment. When the ink is printed, these different heights of fabric will affect the smoothness and density of the ink. Here is an example of a print of a seam. You can see how the ridge affects the ink coverage around it. At times, customers do not mind- and sometimes prefer- this look.

We do our absolute best to give you the highest quality print possible, but when a print goes over the seams, we cannot accept responsibility for any negative effects caused by this issue.

PRINTING OVER THE SEAM OF A SHIRT CAUSE BUILD UP AND INCONSISTENCY DUE TO THE UNEVENNESS AT THE SEAM. WHILE THIS SOLID COLOR PRINT MAY PASS AS A SUFFICIENT PRINT, OTHER DESIGNS INVOLVING MORE COLOR, DETAIL, OR BLENDING, COULD HAVE A WORSE EFFECT.

DIFFICULTIES WHEN PRINTING ON HOODIES

As explained above, we generally do not advise to print across the zipper when printing on a full zip hoodie. The ridge creates a variation in ink coverage. In the event of wanting to printing over zippers, we do have a zipper pallet for our presses that help with the ridges. Due to the different styles of zip hoodies, we cannot ever guarantee a perfect print, however, often the zipper pallet does help in some of the ink build up around the seams.

Additionally, hoodies are one of the more difficult garments to print on, but they are one of the most popular and best-selling styles in the winter. Please be aware of the following issues that can occur when printing on hoodies and other fleece.

- Hoodies are made of thick fabric, which can affect a screen print in many ways. T-shirts are much thinner, which allow for a cleaner print. However, with thick sweatshirts, please be aware that the registration of multi-color prints and underbase layers may have micro shifts. In other words, due to the thicker garment, the design may have a little overlap or you may see a little bit of white underbase when printing on dark garments.

- When printing dark fleeces with multi colors, we are required to print a white under base (think of a layer of white primer) that help the other colors become vibrant. On certain fleeces, when ‘flashing’ or ‘curing’ the white ink with heat, the garment can shrink just little enough to affect the tight registration of the print. Please be aware this is a natural process in screen printing- and that highly detailed and registered artworks may shift a bit in printing.

- Double Lined hoodies can be printed with 1 color and no underbase. The extra layer of fabric does not allow for proper fastening to the press, which restricts us from multiple colors and tight registration.

- Tummy pockets on hooded and zip sweatshirts have to be glued down in order the print over them. Because of this, please be aware that when you receive your garments, there may be some spray adhesive and stick inside the pocket. A simple run through the wash will eliminate this.

- Printing on the hoods of fleecy hoodies will vary due to the brand and style of the garment. Some hoodies have a double lining, which only allow us to a one color print (as explained in the first bullet point). If you want a multi-color design, we would result in heat transfers. Others have a center seam the run all the way through to the top ridge, while others stop towards the back are of the head. If printing on the top of the hood, there may or may not be a center seam. Inquire about that when looking for garments.

- We do have special pallets that have indentations for the zipper and pocket seams, but not every sweatshirt is exactly the same. When you print over these portions of garments, it creates a gap in the print where the ink in the screen does not hit the shirt due to the ridge caused by the seam. For this reason, we do not recommend printing over-the-zipper.

- When you print over the seams, it can throw the registration off. You may see white poking out from under the design.

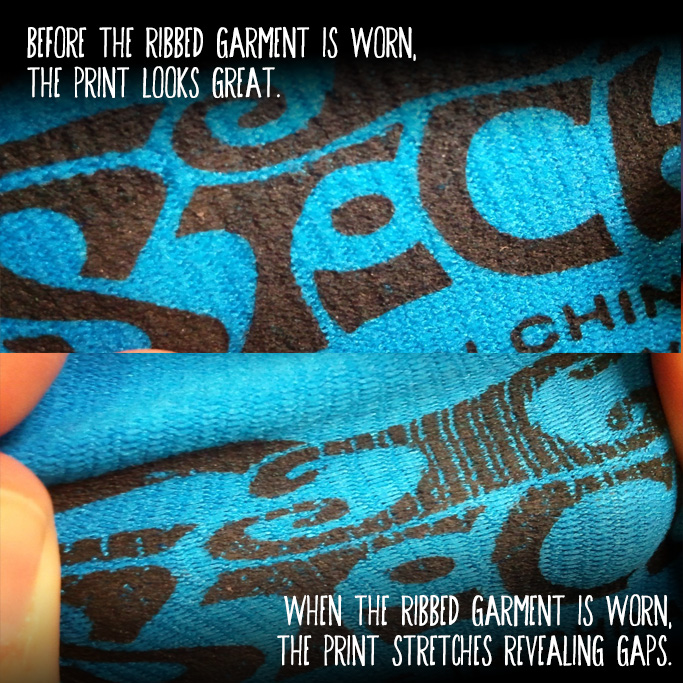

WHY NOT TO PRINT ON RIBBED GARMENTS

Ribbed garments are the ultimate form-fitting garment, as it stretches and fits perfectly for anyone of any size. While it is great for fitting, it serves as a difficult piece to screen print on. When loading a ribbed garment onto the press to screen print, it is not stretched out. When the ink is layed down, it may not reach the lower parts of the ribbed fabrics. When stretching or wearing it, the ribbed fabric stretches, but exposes the under parts of the printed design. Additionally, since the fabric stretches, the sizing and scale of the design is often distorted. Because of these issues, we strongly suggest that you do not print on ribbed garments. Here is an example:

GARMENTS THAT DO NOT SHOW DETAIL WELL

With advancements in screen printing (including high mesh count screens and specialty presses) we can recreate a level of detail with t-shirts that was previously unattainable just 5-10 years ago. However, due to the way some garments are constructed, they will not work well with detail. The following is a list of those garments:

- Ribbed Garments

- Canvas Material (Aprons, Bags, etc.)

- Burnout Tees

- Pique Polos

- Towels

- Beanies (as we suggest embroidery for them!)

These items do not work well with detail because they are not smooth like standard t-shirts.